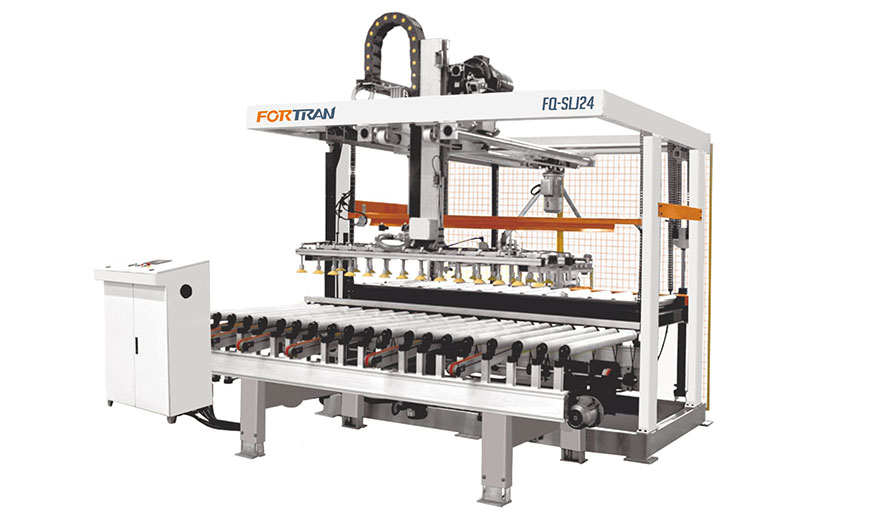

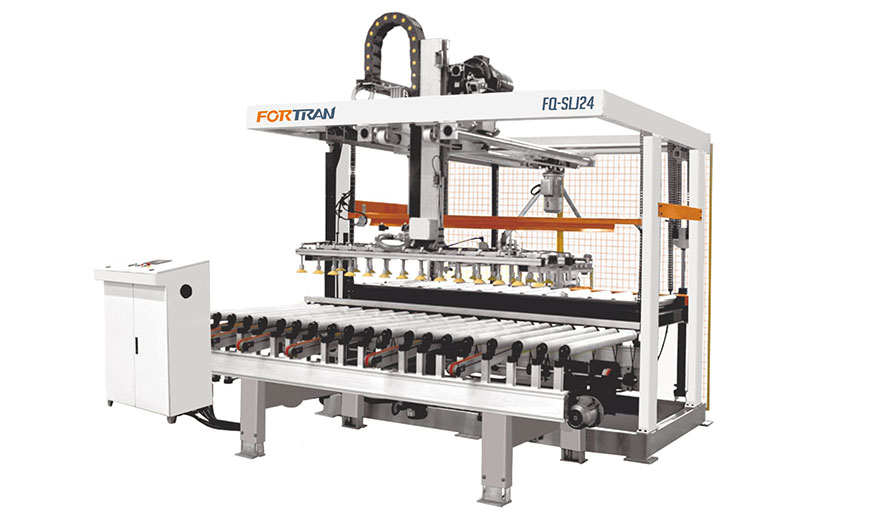

1.Product Introduction

The gantry loader has shown outstanding performance in terms of operational convenience and production efficiency improvement. It adopts a minimalist operation design, which only requires one button to start the whole machine operation, and can be quickly mastered without complex training, greatly reducing the threshold for manual operation. This simple and efficient operation mode not only significantly reduces reliance on professional operators, thereby saving a lot of labor costs, but also directly improves production efficiency by reducing human operation errors and shortening preparation time, making the material loading and unloading process more compatible with the overall production line.

In the specific operation process, the equipment exhibits precise and orderly characteristics: when the panels are placed in the preset order and transported to the roller conveyor of the four column unloader, the vacuum suction cup of the gantry loading and unloading machine will quickly respond, accurately adsorb the panels and smoothly transfer them to the electric roller conveyor with a translation device. The entire process is highly automated and smoothly connected, which not only ensures the safety and stability of panel handling, but also further strengthens the continuity of the production process, laying a solid foundation for the efficient development of subsequent processes

2. Product Parameter (Specification)

Four Pillar Discharger:

| Model | FQ-SLJ24 |

| External Dimension | L3000*W2400*H3300mm |

| Panel length | 300-2400mm |

| Panel width | 300-800mm |

| Panel thickness | 8-60mm |

| Loading capacity for suction | 40kg/m² |

| Loading capacity for table | 1500kg |

| Maximum height of panel | 1300mm |

| Total power | 6.75KW |

| Speed | 8-12 times/min |

| Roller diameter | φ89 |

| Main beam | high-strength square steel |

| Pneumatic component | AirTAC |

| Electric device | Schneider |

| PLC controlling system | Delta/ Inovance |

| Guide rail | Hiwin |

3. Four Pillar Discharger Feature And Application

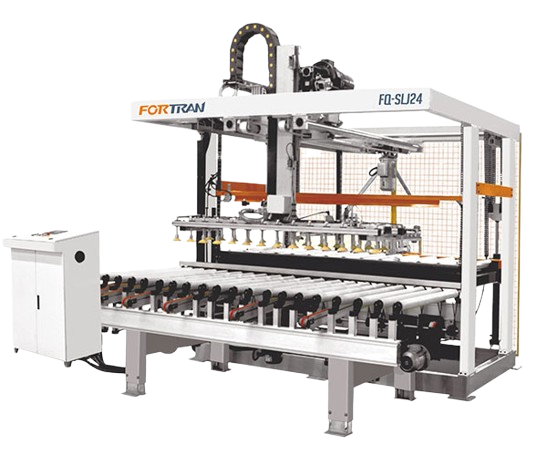

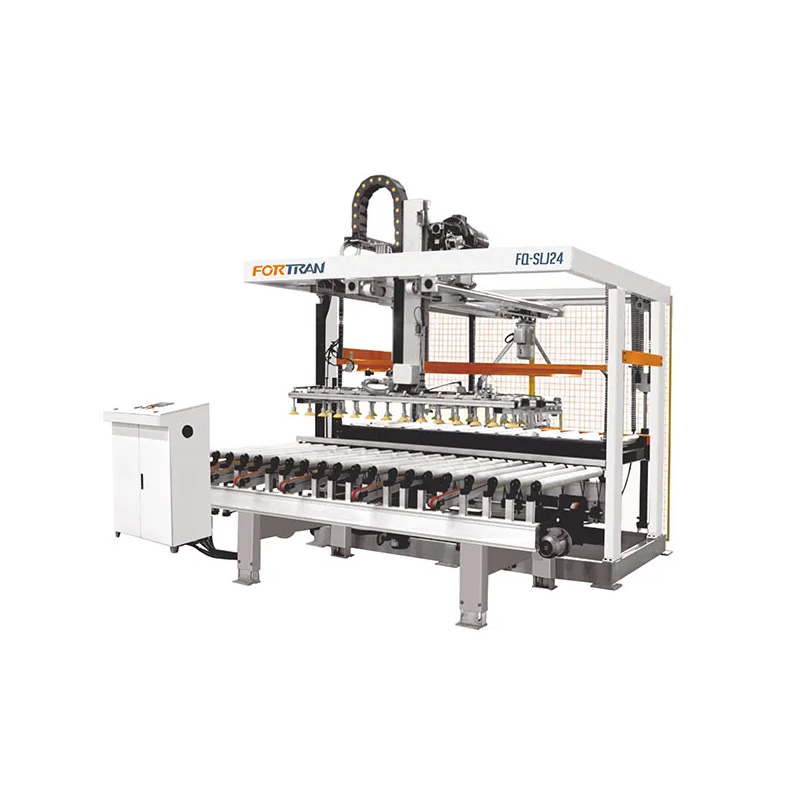

1.Four Pillar Discharger The main beam is made of high-strength square steel material, and the frame and integral square tube are precisely spliced together. It not only has super strong bearing capacity, but also ensures smooth operation of the equipment during operation. The overall structure is stable and reliable, providing a solid foundation for efficient operation.

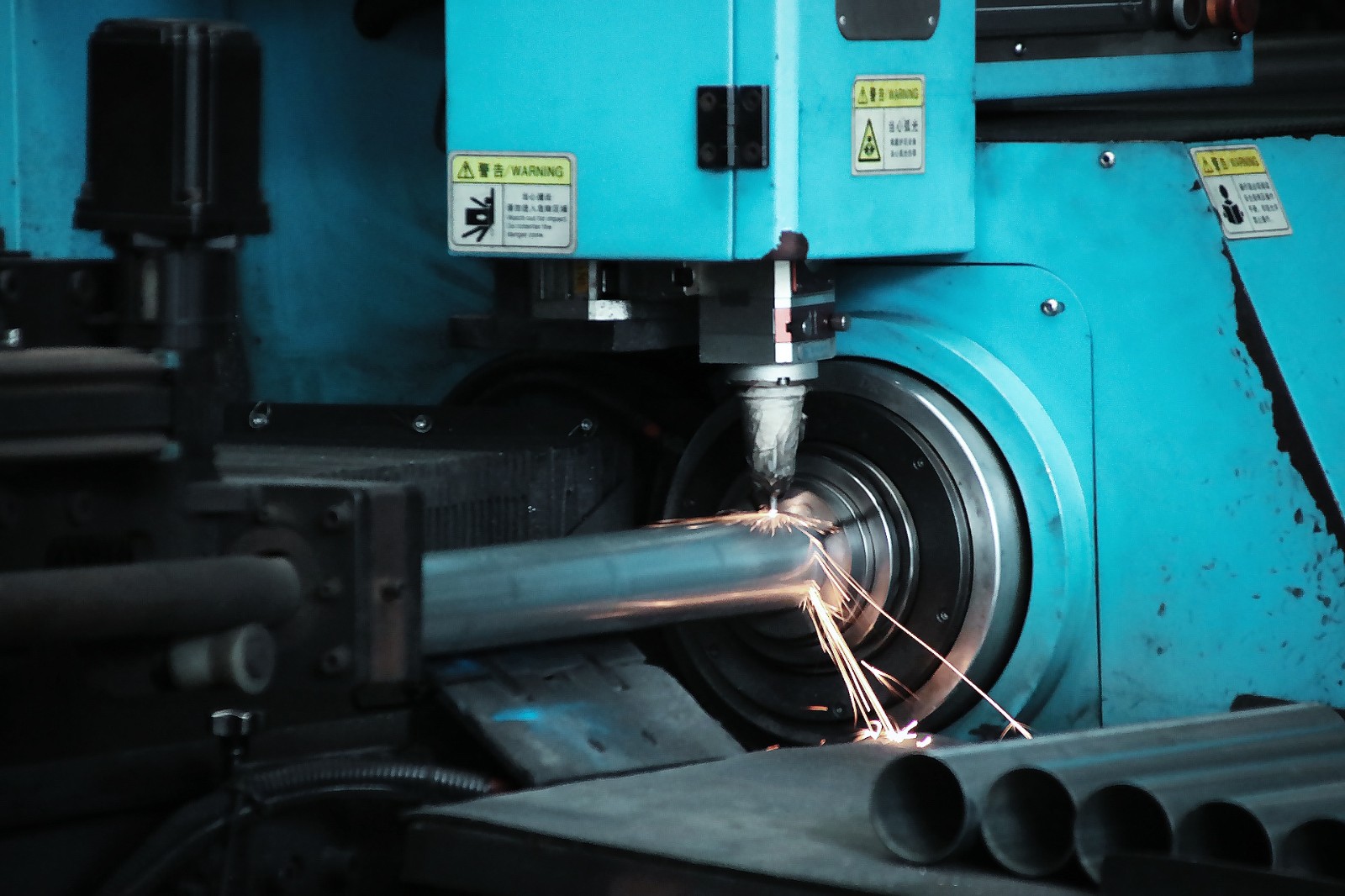

2.Four Pillar Discharger The connection part is welded by Japanese OTC robots to achieve high-precision welding effect in one molding, which not only ensures the firmness and sealing of the connection, but also improves the consistency and stability of the overall structure, effectively reducing maintenance costs in the later stage.

3.Four Pillar Discharger Equipped with Taiwan Delta servo motors, it accurately controls the up and down movement of the vacuum cup, while ensuring smooth and stable horizontal operation. Whether it is high-speed operation or fine operation, it can maintain excellent stability and response speed, greatly improving operation accuracy.

4.Four Pillar Discharger The gantry loading and unloading machine uses high-quality helical guide rails, which have better wear resistance and stronger lubrication ability compared to traditional straight guide rails. They can maintain good working conditions during long-term high-frequency operation, significantly extending the service life of the equipment and reducing operating losses.

4.Four Pillar Discharger Details